|

Why is the UK’s manufacturing sector not investing more in robotics, when the rest of the world is rapidly embracing innovation and automation? The UK is currently languishing at 24th in the world robot density rankings, making it the only G7 country to sit outside the top 20. With few homegrown solutions, the UK lacks the skills, confidence and mindset required to accelerate robotic adoption. Education is key. Robotics is not just about costly, precision manufacturing processes. Nor do companies require an expensive fleet of robots to replace the human workforce. Just one or two Autonomous Vehicles (AVs) can work side by side with staff, undertaking the tedious repetitive activity, improving productivity and freeing up people to undertake more interesting roles. Robotics can be quickly added to any business but with SME manufacturers under intense pressure due to rising costs and staff shortages, the onus is on the automation industry to make adoption easier. From offering Robotics as a Service (RaaS), to simple, short contracts and hands-on support, Paul Rivers, Managing Director, Guidance Automation, insists it is imperative that the automation community comes together to support firms to embrace robotics and ensure the UK’s reputation as a nation of manufacturers continues to thrive. Global Adoption Gap Multiple trends are converging to accelerate the adoption of automation throughout the manufacturing sector. For UK manufacturers, the shift to near sourcing to reduce the reliance on Far East suppliers should be provoking a surge in demand. However, with most businesses still struggling to recruit and retain staff with key skills, handling existing orders is difficult. Automation is the only way to deliver the quality and reliability required to meet new customer demand without adding staff – yet the UK lags a long way behind global competitors when it comes to the adoption of critical technologies, including robotics. While the use of robotics has traditionally been associated with Far East innovators in China and South Korea, countries across Europe are accelerating their adoption. The IFR World Robotics Industrial Robots 2022 report reveals that Slovenia, Slovakia, Finland and Hungary are now outpacing the UK when it comes to the adoption of robotics. Indeed, with the number of new robot installations down 7% year-on-year, the UK has an average manufacturing robot density of 111 robots for every 10,000 employees – a long way below the global average of 141 and considerably lower than the top performing nation of the Republic of Korea (1,000) and the European frontrunner, Germany (397). The figures show a global recognition that robotics is making a vital contribution to manufacturing efficiency and effectiveness, especially in light of global skills shortages. The implications for the long-term success of UK manufacturing are concerning unless the industry comes together to ease the adoption of automation. Financial Concerns The hesitancy around automation investment throughout the manufacturing sector is understandable, given the lack of economic confidence and widespread disruption that has plagued business leaders for the past few years. The majority of manufacturing companies have focused heavily on cost reduction, but margins are still so low that it can be hard to build a business case for any significant capital investment. In addition, company resources are stretched at every level, including senior staff. The great resignation has affected the C-suite, leaving management teams with no time for long drawn-out product assessments or complex contractual negotiations. Many of these businesses have also been affected by poor automation experiences in the past: nearly 50% of SMEs that have tried some automation and had under par results, say that they would not try again. This is an attitude and experience that has to change – and it emphasises the importance of getting the right partner and advice at the outset to ensure optimal results. However, the onus is on the automation industry to make investment easier, simpler and more accessible to entice manufacturers to explore automation and robotics. For example:

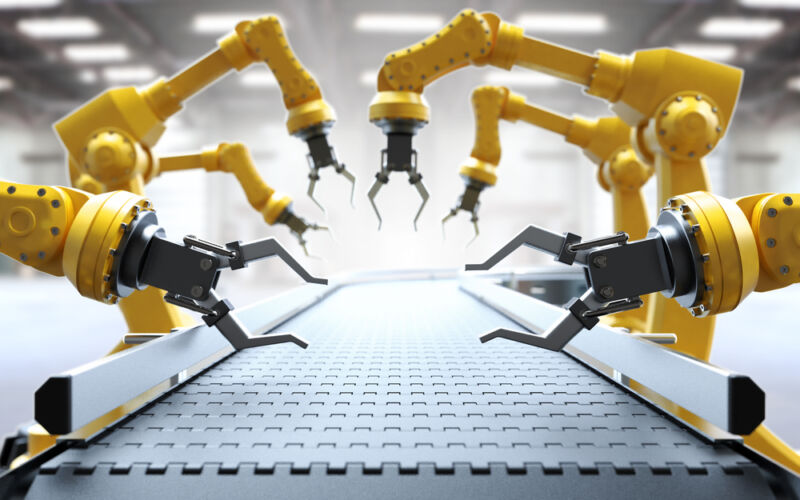

Changing Perceptions The automation industry also needs to be far more proactive in allowing businesses to see robots in action. The lack of UK-developed robots has without any doubt contributed to the slow uptake of the technology – just look at the higher adoption in countries such as Poland, where homegrown robotic development is accelerating the understanding of, and skills in, the technology. As a result, far too many UK businesses have failed to grasp the ease with which robotics can be introduced alongside the workforce. There is still a perception that Autonomous Vehicles, for example, have to be purchased in a fleet to replace warehouse staff. Or that robotics within manufacturing is about creating the extraordinary precision used within expensive, highly efficient automotive plants. In reality, just one or two robots can add efficiency for a manufacturing SME, especially if they can allow staff currently used to undertake repetitive, simple jobs such as moving goods from stock to the production line or finished goods to packing, to be redeployed into more fulfilling work. Robots can work multiple shifts – and will take themselves off for charging when required. They can have different tops or attachments, depending on the business need, which allows businesses to try robots in different areas and applications. And with a flexible contract arrangement, companies can add or remove robots as required – even keeping them on site until peaks in demand, and only paying when the AV is turned on. Conclusion With clear signs that business confidence is improving, it is now vital that manufacturing organisations explore opportunities for change. But that will not happen unless the automation community accepts it must do far more to both demonstrate to manufacturers that innovation and robotics can deliver real benefits and make investment far simpler, quicker and low risk. Building a relationship between an SME and automation provider takes time – and the onus must be on the provider to go the extra mile. Taking an Autonomous Vehicle to a manufacturer and letting it operate alongside employees, for example, is an easy step to demonstrate how simply robots can be added to the existing workforce. Helping companies through the adoption and integration process is key to building confidence in automation. And the benefits to everyone are clear. Companies that have invested in robots quickly see the value. They rapidly identify new opportunities for deployment and suggest areas of innovation – such as the addition of a robotic arm to allow a robot to pick up items. They recognise the importance of releasing scarce staff resources from tedious jobs and the retention benefits associated with giving people more interesting and valuable jobs, such as quality assurance, that robots cannot do. It is only by taking the time to help UK manufacturers to invest in automation and robotics that the automation community will achieve the goal of reinvigorating UK manufacturing. |

Invigorating the UK’s Robotic Investment