A new encoderless, field-oriented control method (vector control) from KEB Automation provides users (maximum torque per ampere) with control over the entire speed range. This benefits servo drives for positioning applications, for example, where high concentricity is required even at the lowest speeds. The method is also suitable for flywheel energy storage systems that are operated at the torque limit over the entire speed range. Permanent synchronous, IPM and synchronous reluctance motors can therefore provide a performance that is in no way inferior to operation with an encoder.

Lower susceptibility to faults, less wiring effort and, ultimately, reduced costs: the advantages of encoderless motor control are numerous and are particularly convincing when the performance can compete with encoder-based control. In order to perform reliably in the lower speed range, KEB has developed and patented a sensorless control system, Complex Vector Sensorless Control (CVSCL).

“The new motor control method enables the determination of position, speed and electrical motor parameters. Thanks to CVSCL, a speed-dependent selection of different encoderless control methods is not necessary,” says Achim Schöke, Deputy Head of Development Electronics at KEB. This would eliminate problematic switching processes, which can lead to instabilities due to transient processes.

High-frequency signal makes music

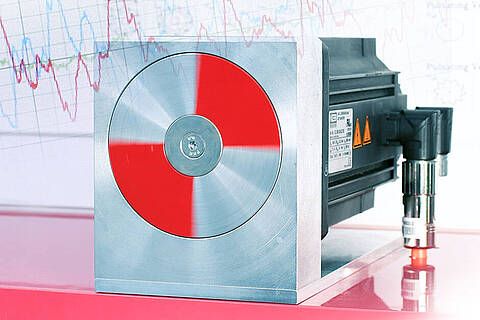

The encoderless control algorithm, which is also used to adapt parameters, can in principle be fed with any input signals. In a demonstration model set up at KEB, high-frequency signals were injected into the motor via a COMBIVERT F6 drive controller https://youtu.be/3WNzj86euVI

“Frequently used injections are pulsating and rotating signals. Basically, pulsating signals can be represented by superimposing two signals that rotate at the same frequency in opposite directions,” explains Schöke.

The proof of the free choice of injection signals for encoderless control is provided in the model setup by using music. The songs that the motor plays are created by additionally injected motor voltages. These are first high-pass filtered and then superimposed on the setpoint voltages of the field-oriented control. The resulting voltages are finally impressed into the motor with the help of the power semiconductors of the frequency inverter.

The control concept represented by this setup is implemented via dSPACE’s MicroLabBox. This provides a real time solution with high computing power and only low I/O latencies. “It is planned that the new encoderless control concept will flow into the KEB firmware. For application areas where the drive must be operated safely in the lower speed range up to and including zero speed, or where high speeds must be reached quickly and safely from the start, CVSCL is a true enrichment,” says Schöke.

For more information, please visit www.keb.co.uk